- The key attribute that sets butyl seal putty tape apart is its malleability. It can easily conform to irregular surfaces, ensuring a comprehensive and long-lasting bond. Unlike traditional tapes, it does not harden or crack over time, maintaining its flexibility and resilience even under extreme weather conditions. This characteristic makes it ideal for outdoor applications where exposure to sunlight, heat, and cold is inevitable.

Generally speaking, manufacturers use three different adhesive types in combination with the backing material to produce a final “tape” product. Though these adhesive types can be subdivided into subgroups, the main categories are as follows:

Electrical control boxes are endowed with electrical components such as circuit breakers and transformers since they are engineered to oversee electrical distribution. Their application range and scope transcend both industrial and residential use. Common examples of electrical control boxes include;

One of the reasons Flex Tape is favored by many is its ease of use. Simply cut the desired length, peel off the backing, and apply it to the surface you want to repair. It requires no tools, and its flexibility means you can easily maneuver it into place, even in tight spots.

Silicone tape is a useful addition to your toolbox as it can be used to make emergency repairs to almost anything that needs an airtight or watertight seal. It can be applied quickly and easily, with no need for adhesive.

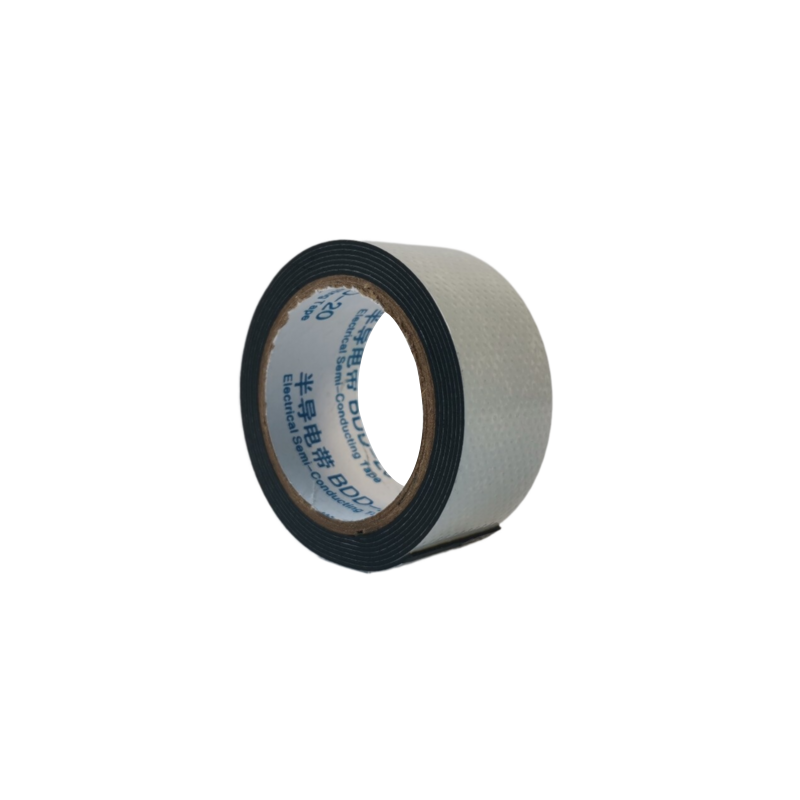

Low Smoke and Halogen-freeSelf-bonding Fire-resistance Tape

Butyl rubber rolls find applications in many areas, including automotive, construction, and consumer products. One of the most common uses is in the automotive industry, where butyl rubber is employed in manufacturing inner tubes for tires, gaskets, and seals. Its impermeability helps to reduce air leakage, enhancing tire performance and longevity.

butyl rubber roll

The key feature of amalgamating rubber tape is its ability to effectively bond to itself when stretched and wrapped around an object. This self-amalgamating characteristic creates a strong and durable seal that is resistant to water, chemicals, UV rays, and extreme temperatures. As a result, this tape is widely used for electrical insulation, plumbing repairs, cable management, and automotive applications.

Hydraulic Control Boxes

In understanding everything you need to know about electrical tape, you should learn a thing or two about tape selection. So, what should you reflect on when choosing which type of electrical tape to use for your network? CableWholesale looks at other elements of electrical tape to consider when investing.

What are Rubber Based Adhesives?

3M also makes an electrical tape made of silicone rubber for applications where Class “H” (180°C/356°F) temperatures are encountered i.e., silicone rubber cables.

5. Test the Seal Once applied, check to see if the seal is tight. You can do this by attempting to slide a piece of paper between the door or window and the frame; if it doesn’t slide out easily, your installation was successful.

adhesive rubber seal strip. Refrigerators, ovens, and washing machines, among others, utilize these strips to ensure airtight seals, preserving food freshness, optimizing energy consumption, and preventing water leakage.

adhesive rubber seal strip. Refrigerators, ovens, and washing machines, among others, utilize these strips to ensure airtight seals, preserving food freshness, optimizing energy consumption, and preventing water leakage.Seal out moisture from electrical connections